CNC Milling Workflows¶

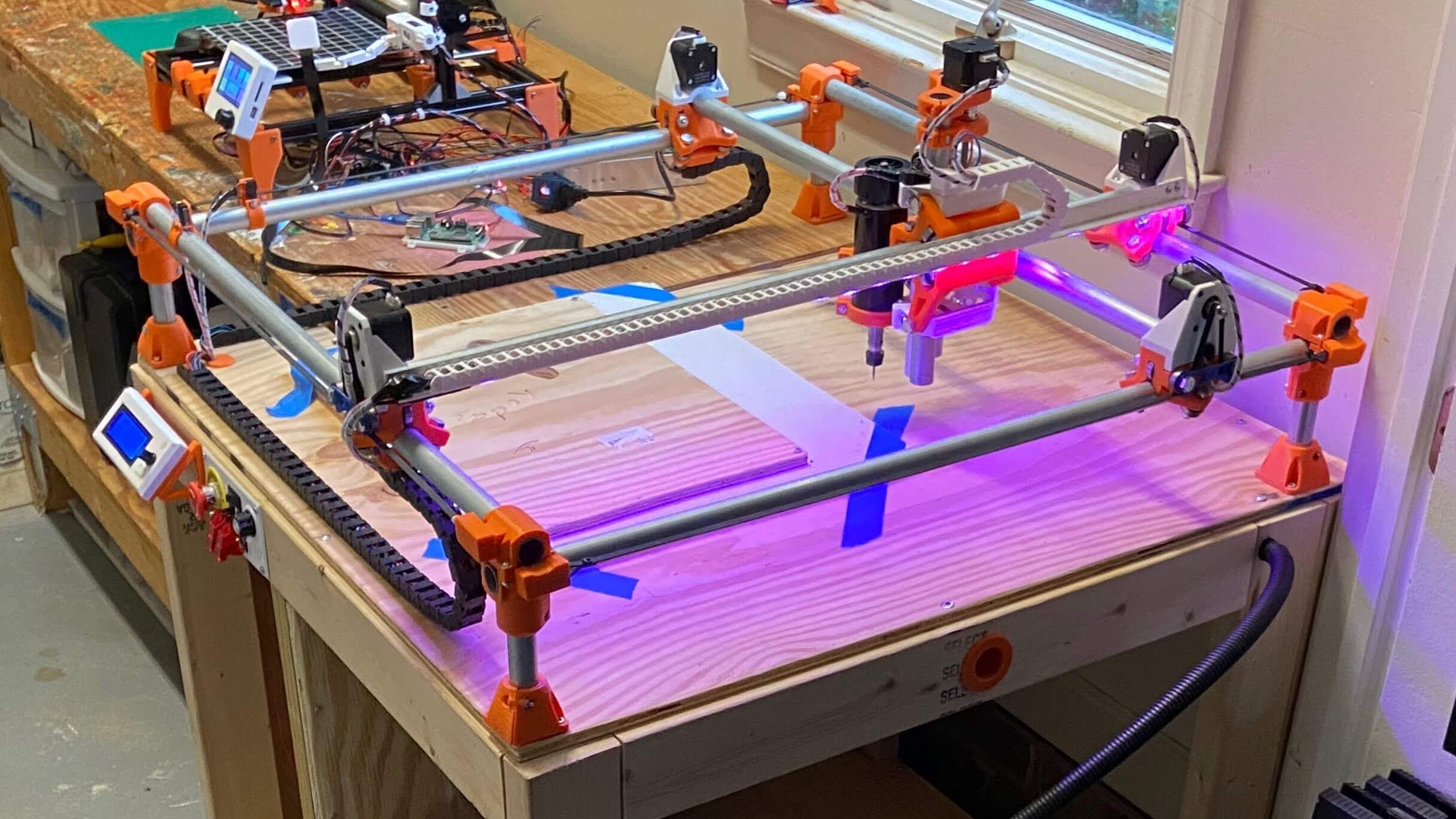

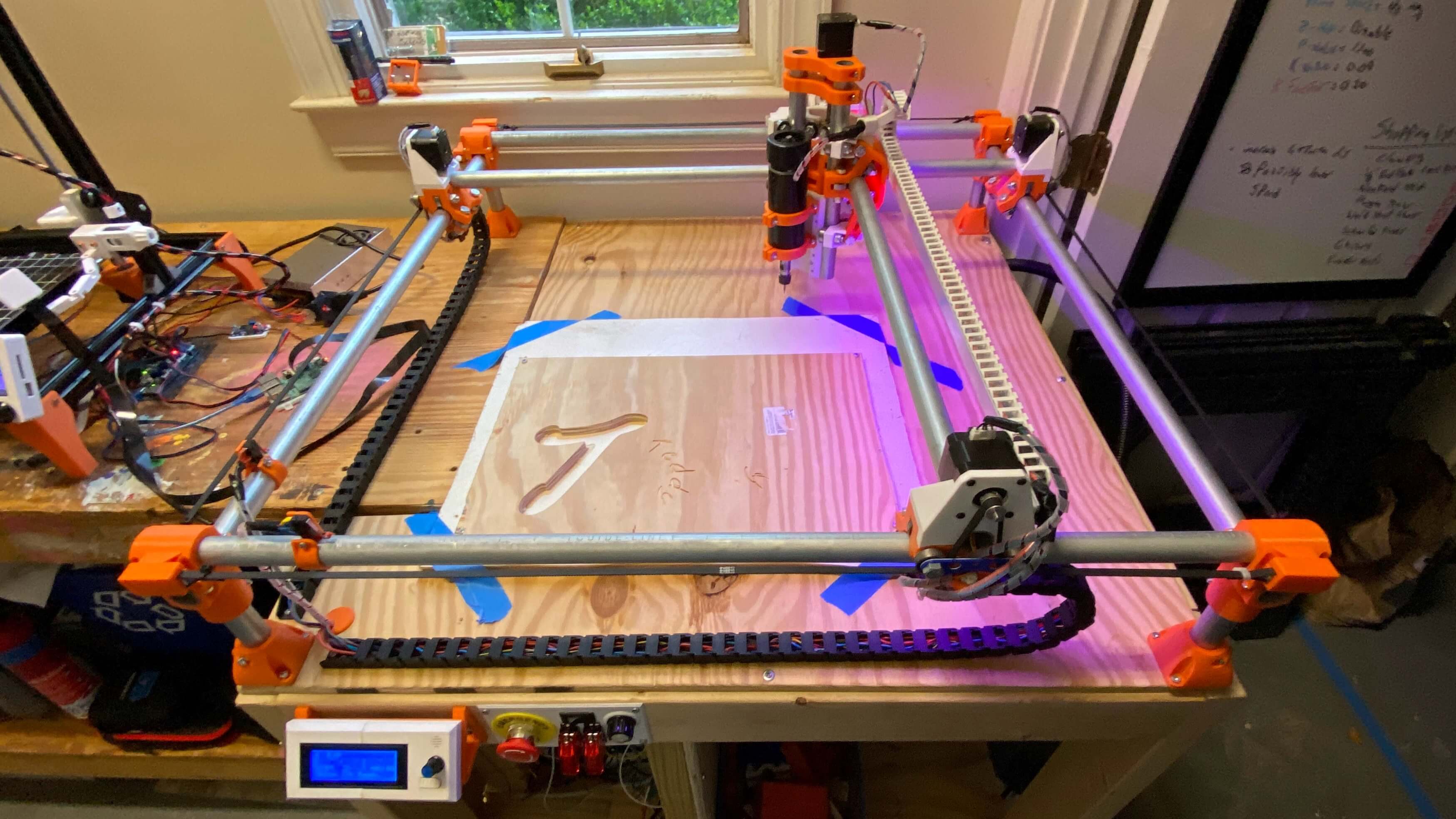

Subtractive manufacturing is a process I’ve always found mesmerizing. Although additive processes such as 3D printing allow for the creation of something from seemingly nothing, I believe it’s even cooler to watch the morphing of existing stock into a different object. Despite this interest, I feel as though I’ve barely scratched the surface of CNC - primarily focusing on PCB milling in my subtractive manufacturing projects. I made a first attempt to dive into more subtractive manufacturing work a couple of years ago now when I built V1 Engineering’s original MPCNC.

I absolutely loved building this machine and recommend it to all interested in understanding the workings of CNC, yet I don’t mill on mine all that often, I find more use in using the machine as a GCode dev platform for some of my other projects.

Since my initial attempted steps with the MPCNC, I’ve become more versed with CNC milling due to exposure during my Fab Academy Week 7: Computer Controlled Machining assignment. For this assignment, I used the CLS Fab Lab’s ShopBot PRSalpha to mill the plywood fish tank housing for my Fab Academy Final Project. I continued my milling work over the summer, running the ShopBot almost daily over July for Young Engineers of Today’s Summer Camps. Last fall, our lab picked up a Bantam Tools Desktop CNC Milling Machine, Bantam’s flagship machine, capable of super-rapid prototyping when partnered with their Milling Machine Software.

This article attempts to serve as a complete guide for CNC milling, covering machinist jargon, material standards, feeds and speeds, CAM workflows with Autodesk Fusion 360 & Vectric Aspire, and milling workflows for Shopbot & Bantam Tools machines - all through a collection of milling micro-projects ranging from a 1 to 1.9 Million scale mill of Mars’s Gale Crater to brass wax seals

Milling Micro-Projects

This page strays from my normal single-project documentation style, opting to cover different CAM & milling workflows via a collection of micro-projects. In a similar approach to the “Constantly Updating” status of my Lithophane Experiments article, I plan to continually expand the content of this article with any additional milling micro-project I complete. Initally, the page will just host material reference & a feeds and speed calculator. That being said, be sure to stay tuned for future updates!

Feeds & Speeds¶

Creating a successful subtractive manufacturing toolpath can be a bit more intimidating than slicing for additive manufacturing. Not only can you jeopardize your stock material, but incorrect feeds and speeds can also yield a hazardous environment & potential machine damage. There is no streamlined answer to find the right feeds and speeds, ideal values depend on numerous variables & feeds and speeds may not remain constant from job to job. This section provides a starting place for feeds and speeds, with general values provided as well as a calculator for the required inputs in your toolpath. This is by no means a universal key and necessary precautions & alterations should be made to provide values to mesh with your manufacturing workflow. Often the manufacturer of your tool & your machine will provide generic feeds and speeds for your specific equipment. Operator input is required to achieve successful & safe cuts, often you’ll be able to hear machine strain - a telltale sign of poor cutting. Trial and error adjusting is necessary to achieve the sweet spot for your feeds and speeds.

Feeds & Speeds Terminology

Tool Diameter-

The diameter of the endmill. When Profile milling or Through Cutting stock, it is best to keep the Tool Diameter ≥ 1/6 Stock Thickness, preserving the integrity of the endmill while allowing for full passes. Larger tool diameters yield shorter cut times when removing a lot of material, while smaller diameters allow for higher detail to be reached. It is typically best to utilize both larger and smaller diameter endmills, using the larger to clear the bulk of stock material, while finishing the mill with a smaller diameter tool to achieve the best detail.

Flute Count-

The number of individual flutes an endmill has. Flutes are the upward running cutting edges on an endmill. Lower flute counts allow for better chip & heat clearance from the cutting edge, while higher flute counts provided a smoother finish to a part. Stock materials that require a high surface speed also require higher flute bits, and vice versa with lower surface speed requirements. One to Two flute bits will suffice for prototyping with soft plastics & waxes. Two or more flutes will typically be needed for harder plastics (such as HDPE), woods, and metals.

Surface Speed-

The speed at which the tool’s cutting edge travels through the stock. Surface Speed is dependent on both the stock & endmill materials. Maximum surface speeds are typically published by your endmill’s manufacturer and do not need to be derived experimentally. Staring jobs at ≤ 50% of the maximum provided value is the best practice to allow for ample time to ensure the successful operation of your machine.

Chip Load-

The thickness of offcut ‘chips’ removed with each flute per revolution of the endmill. Maximum chip load is typically provided by the endmill’s manufacturer, based upon the tool’s characteristics. Finding a balance between chip load extremes is crucial for the safety of you and your machine. While larger chip loads yield shorter machine time, they also put greater forces on your endmill, potentially pushing the bit towards its point of rupture. On the other hand, smaller chip loads increase machine time, while expelling waste and heat from the tool at a slower pace, thus risking overheating and potential fire. Safe chip load values usually fall between 0.001” & 0.010”0.0254mm & 0.254mm.

Spindle Speed-

The number of revolutions made by the endmill in a unit of time (RPM is standard). A Lower RPM yields a higher quality surface finish & more cutting power, while a higher RPM decreases machine time. For optimal milling operations, use a higher RPM for roughing passes & a lower for finishing.

\[ Spindle Speed (RPM) = {Surface Speed (ft/min) \over π ∗ {1 \over 12} ∗ Tool Diameter (in)} \]\[ Spindle Speed (RPM) = {Surface Speed (M/min) \over π ∗ {1 \over 1000} ∗ Tool Diameter (mm)} \]

\[ Spindle Speed (RPM) = {Surface Speed (ft/min) \over π ∗ {1 \over 12} ∗ Tool Diameter (in)} \]\[ Spindle Speed (RPM) = {Surface Speed (M/min) \over π ∗ {1 \over 1000} ∗ Tool Diameter (mm)} \] Feed Rate-

The speed at which the machine moves the tool through the stock. Finding the right feed rate is crucial for the safety of you and your machine. Excessively high feed rates cause excessive load on the cutter, leading to cataclysmic failure of the endmill, spindle, and machine. Feed rates that are too low produce unnecessary vibration on the machine, leading to poor surface finishes & potential cutter failure.

\[ Feed Rate (in/min) = Spindle Speed (RPM) ∗ Flute Count ∗ Chip Load (in) \]\[ Feed Rate (mm/min) = Spindle Speed (RPM) ∗ Flute Count ∗ Chip Load (mm) \]

\[ Feed Rate (in/min) = Spindle Speed (RPM) ∗ Flute Count ∗ Chip Load (in) \]\[ Feed Rate (mm/min) = Spindle Speed (RPM) ∗ Flute Count ∗ Chip Load (mm) \] Plunge Rate-

The speed at which the endmill is driven down into the stock. The vertically running flutes on an endmill allow the tool to cut horizontally, while vertical plunges are more demanding on the tool. Lower plunge rates prevent tool damage & maintain lower temperatures while boring holes. All plunging cuts should be ramped, as gradual plunging while traveling across the stock will reduce tool stress.

\[ Plunge Rate(in/min) = Feed Rate (in/min) * {1 \over 2} \]\[ Plunge Rate(mm/min) = Feed Rate (mm/min) * {1 \over 2} \]

\[ Plunge Rate(in/min) = Feed Rate (in/min) * {1 \over 2} \]\[ Plunge Rate(mm/min) = Feed Rate (mm/min) * {1 \over 2} \] Stepdown-

The vertical depth of each pass of the tool into the stock. Best practice is to maintain a step down of ≤ 50% of the tool diameter, however, may be increased while milling softer materials. The step down should always remain less than the tool diameter.

\[ Stepover(in) = Tool Diameter (in) * {3 \over 5} \]\[ Stepover(mm) = Tool Diameter (mm) * {3 \over 5} \]

\[ Stepover(in) = Tool Diameter (in) * {3 \over 5} \]\[ Stepover(mm) = Tool Diameter (mm) * {3 \over 5} \] Stepover-

The space between passes of the tool into the stock. While pocketing, a maximum stepover of 50% can be used, however lower stepover values will leave a better surface finish.

\[ Stepover(in) = Tool Diameter (in) * {9 \over 20} \]\[ Stepover(mm) = Tool Diameter (mm) * {9 \over 20} \]

\[ Stepover(in) = Tool Diameter (in) * {9 \over 20} \]\[ Stepover(mm) = Tool Diameter (mm) * {9 \over 20} \]

Material Reference¶

Feeds and speeds are equally dependent on material properties and the specific of your machine & tool. Below I’ve compiled a table of commonly milled stock materials, ranging from woods to plastics to metals. Each material offers a brief description of the stock, as well as average surface speed & chip loads. Chiploads are tool-dependent just as much as they are material-dependent, so be sure to select an adequate load for your tool’s diameter. More conservative chip loads are given on the left, while aggressive loads are given on the right. Conservative values will extend the life of your tool, while the higher loads will catalyze your job time - select a chipload within the provided range based on your needs. As mentioned above, This is by no means a universal key and necessary precautions & alterations should be made to provide values to mesh with your manufacturing workflow. Often the manufacturer of your tool & your machine will provide generic feeds and speeds for your specific equipment. Operator input is required to achieve successful & safe cuts, often you’ll be able to hear machine strain - a telltale sign of poor cutting.

| Material | Description |

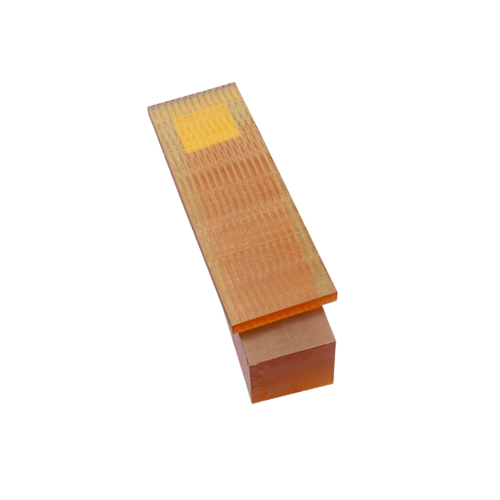

| Wax | A easily milled medium, commonly used for casting cores, molds, and CNC program proofs. |

| Soft Wood | A accessible & stylish medium, not to tricky to mill, often used for large scale parts - Pine, Spruce, Cedar, etc. |

| Hard Wood | Similar benefits to soft wood, can be a bit more costly - Maple, Walnut, Cherry, Ash, etc. |

Medium Density Fiberboard MDF |

An easily machined & finished material, relatively cheap, commonly used for jigs, fixtures, vacuum molds & engraving. |

Oriented Strand Board OSB |

A strong, light weight, cost-efficient material, a great choice for large scale stiff parts. |

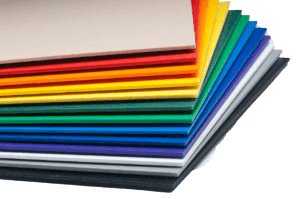

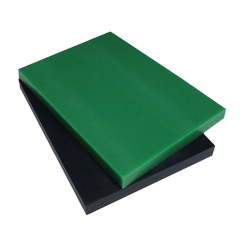

High-density Polyethylene HDPE |

A soft-ish plastic, great for prototyping but a tricky material to mill. |

Polyetheretherketone PEEK |

A high-performance thermoplastic, great for structural applications with resistance to fatigue and stress-cracking. |

Polyetherimide PEI |

A high-performance thermoplastic, with great heat, solvent & flame resistant. Often used in applications with long term steam exposure. |

Polyvinyl Chloride PVC |

An cost efficient & accessible plastic, typically used across industry but offers a cheap & lightweight medium. |

Polyoxymethylene POM |

A general purpose, good all around thermoplastic - also know as Acetal or Delrin. |

Acrylonitrile Butadiene Styrene ABS |

Easily accessed & low cost thermoplastic, commonly used for molding applications. |

Polycarbonate PC |

An incredibly strong and possibly transparent thermoplastic, known for maintained temperature resistance. |

| Nylon | A cost-effective & long-lasting thermoplastic, used in cases of required mechanical dampening or electrical insulation. |

| Acrylic | A lightweight insulating thermoplastic, serves as an effective replacement for glass. |

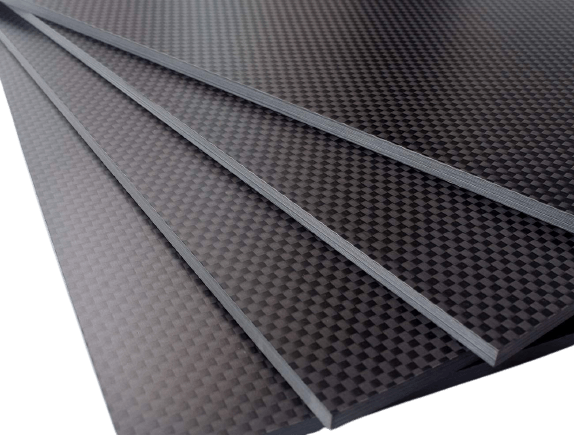

| Carbon Fiber | A strong & lightweight composite of carbon based fibers, desirable for various industrial applications due to its heat & chemical resistance. |

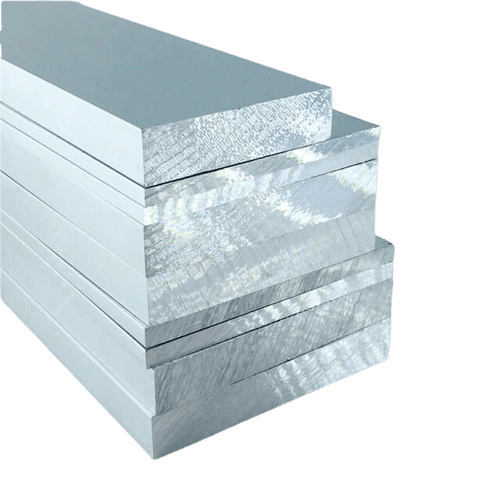

| Aluminium | An accessible, easy to mill metal, seen across thermal & electrical conducting components. |

| Brass | A easy to machine & highly conductive metal, ideal for low friction & intricate parts. |

| Copper | A malleable metal, typically used for its high electrical & thermal conductivity. |

| Steel | An iron alloy with high strength & fracture resistance, typically used in situations requiring its high tensile strength, such as tools & machines. |

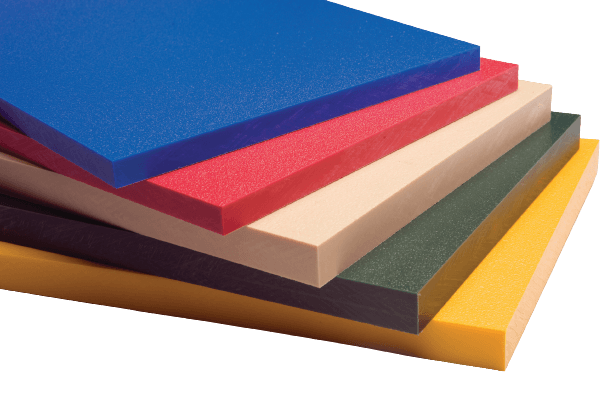

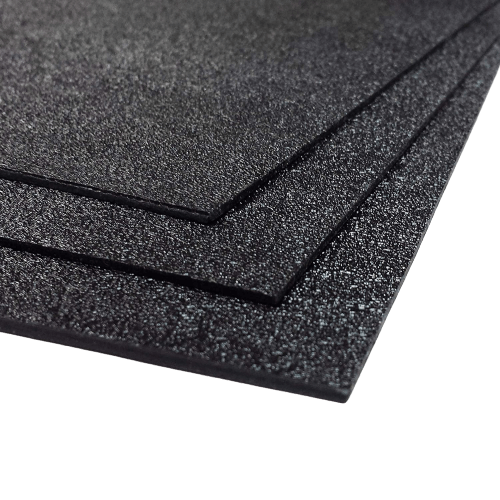

| Insulation Foam | A low cost, accessible & easy to mill material, commonly used for large molds & as cores for lightweight parts. |

Feeds & Speeds Calculator¶

Instructions for Use

Work through the calcuator from top to bottom. First select your coolant prefrence, then input tool diamater and flute count. You may pull reccomended material settings from the table above via the “Material Library” dropdown, or you may under your own. Please note the prior warnings on calcuator dependence: This is by no means a universal key and necessary precautions & alterations should be made to provide values to mesh with your manufacturing workflow. Often the manufacturer of your tool & your machine will provide generic feeds and speeds for your specific equipment. Operator input is required to achieve successful & safe cuts, often you’ll be able to hear machine strain - a telltale sign of poor cutting.

Microprojects¶

An addendum - Jan 2025.

When I set out to write this piece a few years ago, I had the somewhat lofty intention of doccumenting as many different CAD/CAM softwares as I could, providing comprehensive walkthroughs for their usage. By the time I finished assembling and testing the above Material Reference section (believe me when I say this was a lift), I was quite burnt out of this endevour, and so this article just sat, unfinished on this site for a few years.

In hopes of providing a slightly better “conclusion” to this piece, I’ve appended a gallary of project media below, all of which was machined with settings from the above Feeds & Speeds Calcuator. Enjoy!

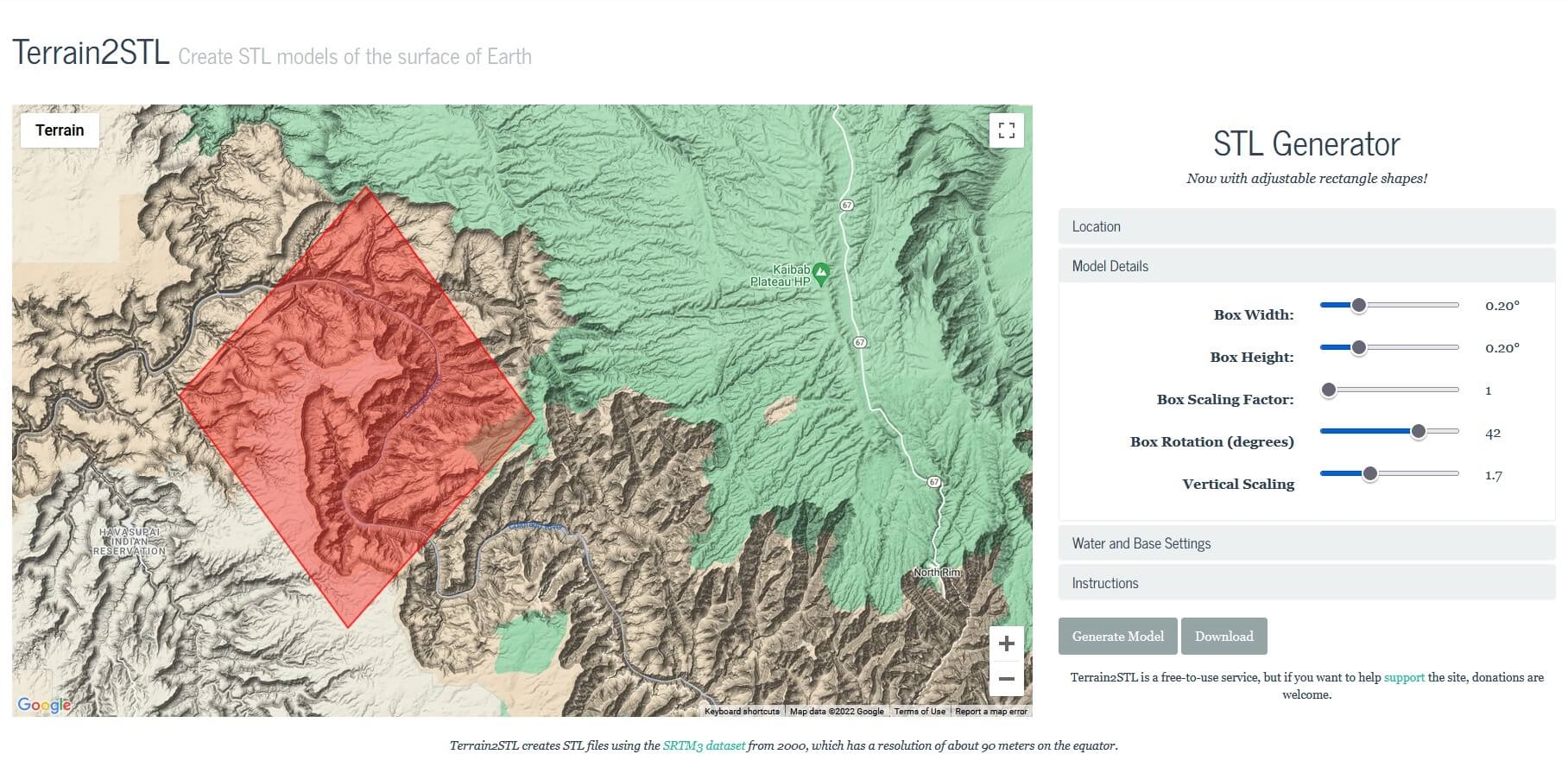

Gale Crater Mill¶

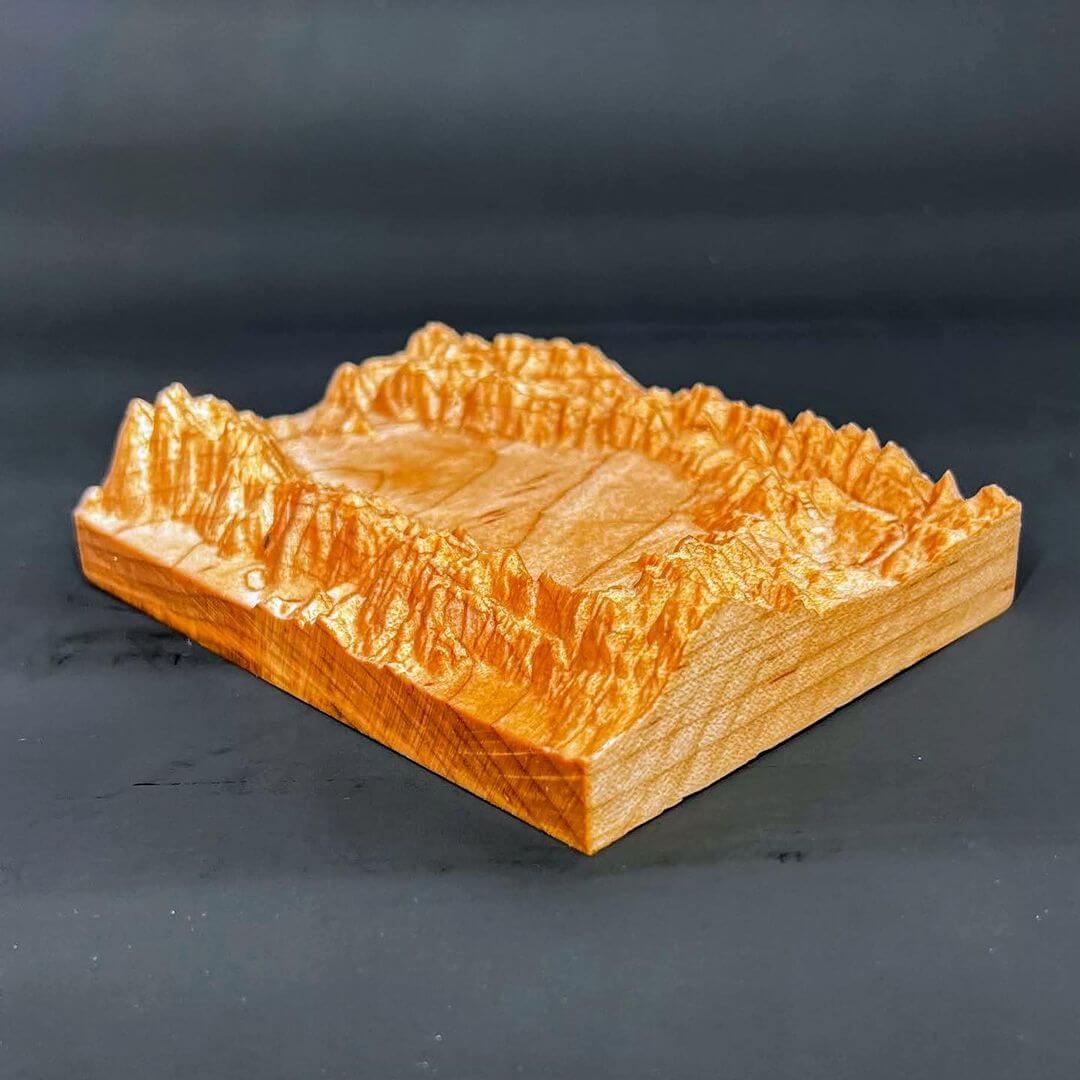

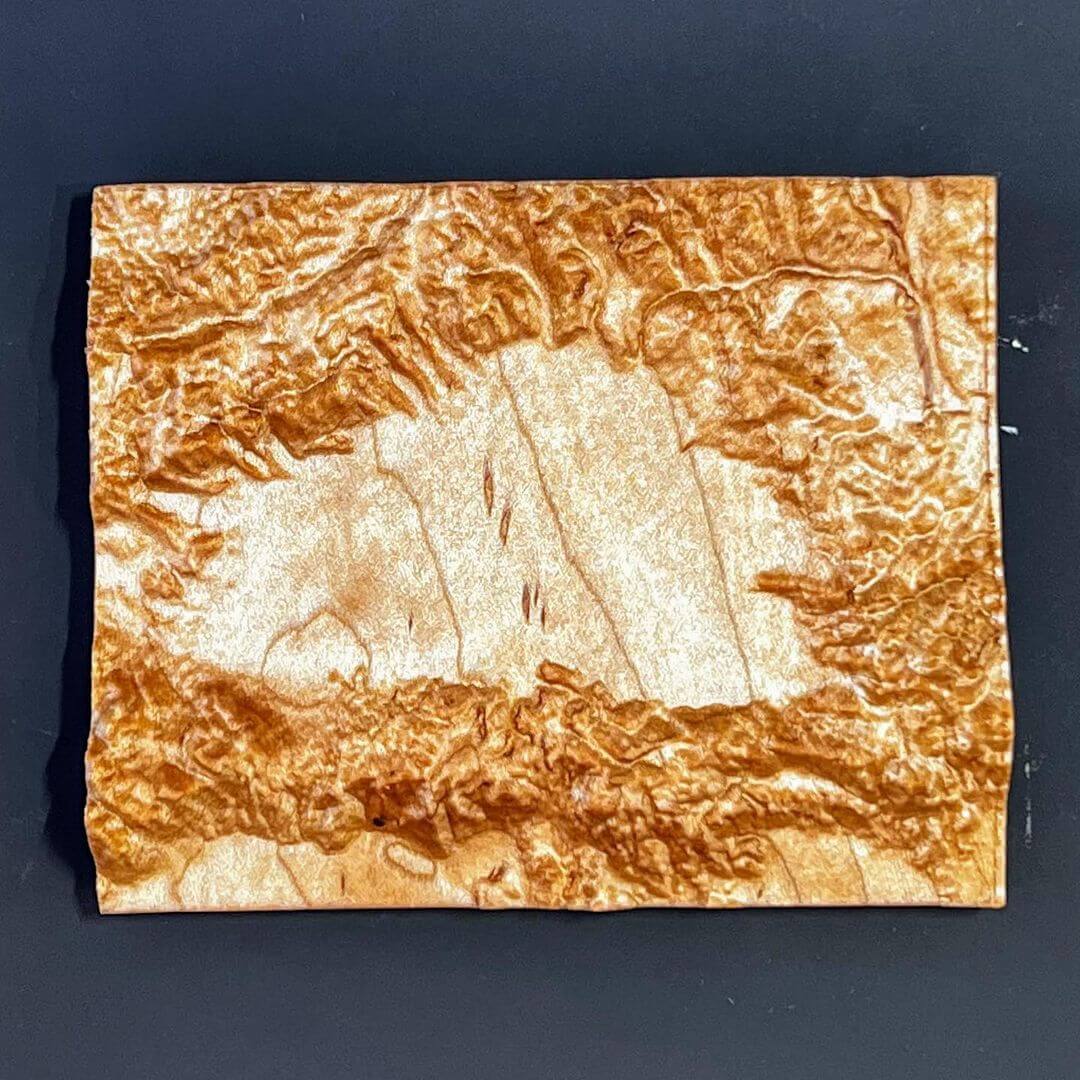

Topography Paper Weight¶

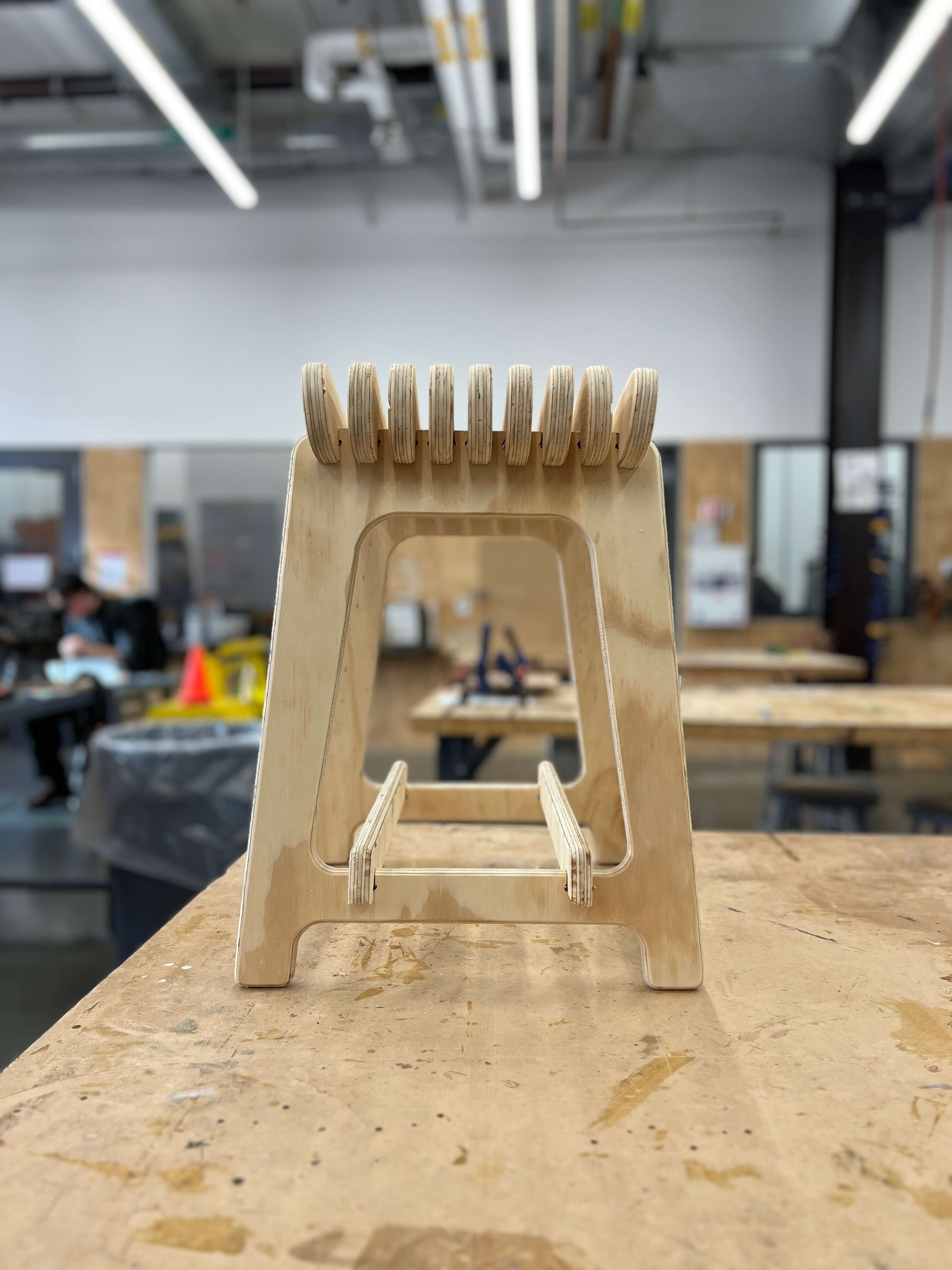

Flat-Pack Stool¶

-

https://www.cnccookbook.com/machining-carbon-fiber-composites-drilling-cnc-tools/ ↩

-

https://dragonplate.com/how-to-cut-carbon-fiber ↩

-

https://www.gutenberg.org/files/12299/12299-h/12299-h.htm ↩

-

https://www.practicalmachinist.com/vb/general-archive/face-milling-pvc-152424/ ↩

-

https://www.precisebits.com/tutorials/spindle-rpm ↩

-

https://pub.pages.cba.mit.edu/feed_speeds/ ↩

-

https://www.protolabs.com/resources/design-tips/cnc-machining-materials/ ↩

-

https://www.3erp.com/blog/cnc-milling-materials-choose-application/ ↩

-

https://www.hubs.com/knowledge-base/selecting-right-cnc-material/ ↩

Enter your email to receive the occasional update.